Motion Control: Choosing between Central or Decentralized Control?

What determines the choice between central or decentralized control of a motion control application? In a conversation with Application Engineer Roel van der Mark, we explore the machine control hierarchy, the advantages of both central and decentralized motion control intelligence, and why the mutual dependence of axes in an application influences our decision. Through concrete examples, you will learn more about VARIODRIVE’s approach and mindset.

Servo drives were simple instruments for a long time, with controllers that could regulate torque or speed, for instance, and often, the motion control was centrally organized. However, processors introduced in the 1970s became faster and more powerful over time, allowing more intelligence to be added to servo drives. As a result, machine builders increasingly opted for an architecture with decentralized motion control to manage the necessary movements.

Until a tipping point was reached, where processing power, speed, and the communication speed of bus systems converged. Suddenly, a central machine control/PLC could perform all calculations and had the bandwidth to control all motion. Central control regained preference.

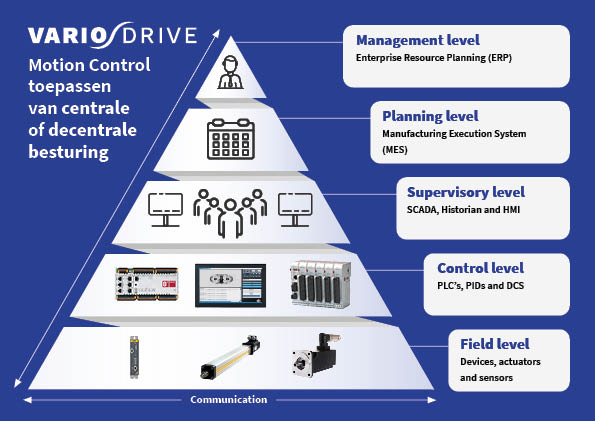

Machine Control Hierarchy

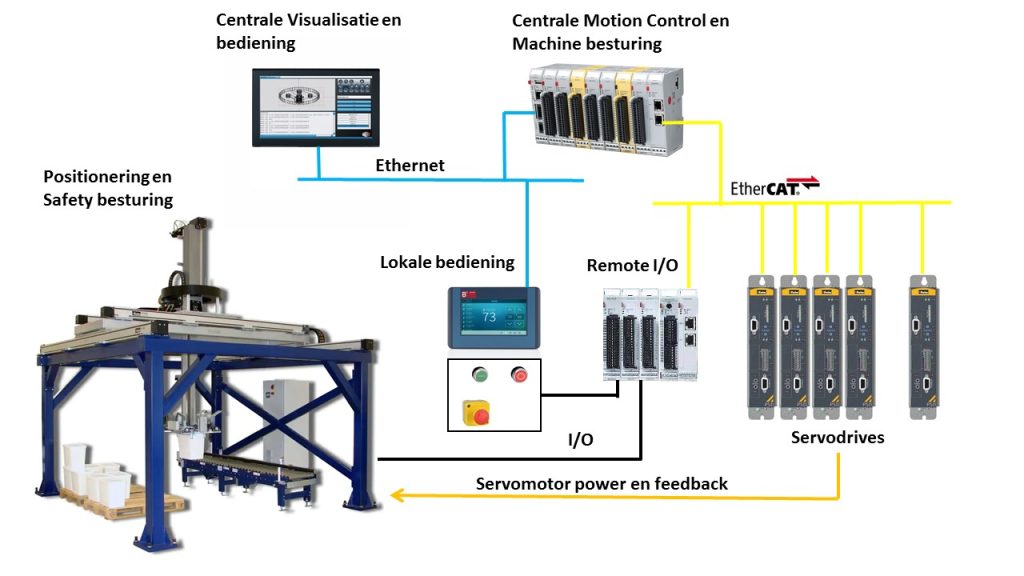

We’ve already passed another turning point, and the complexity of our manufacturing processes has significantly increased. Nowadays, we refer to a machine control hierarchy where both central and decentralized systems play different roles. These control systems are applied at the ‘device’ level, but the distinction is also possible at the higher ‘control’ level. Data and control information are exchanged within the application through communication layers. A central system at the ‘control’ level can control both central and decentralized systems at the ‘device’ level using technologies like EtherCAT.

Application engineer Roel van der Mark explains this with an example:

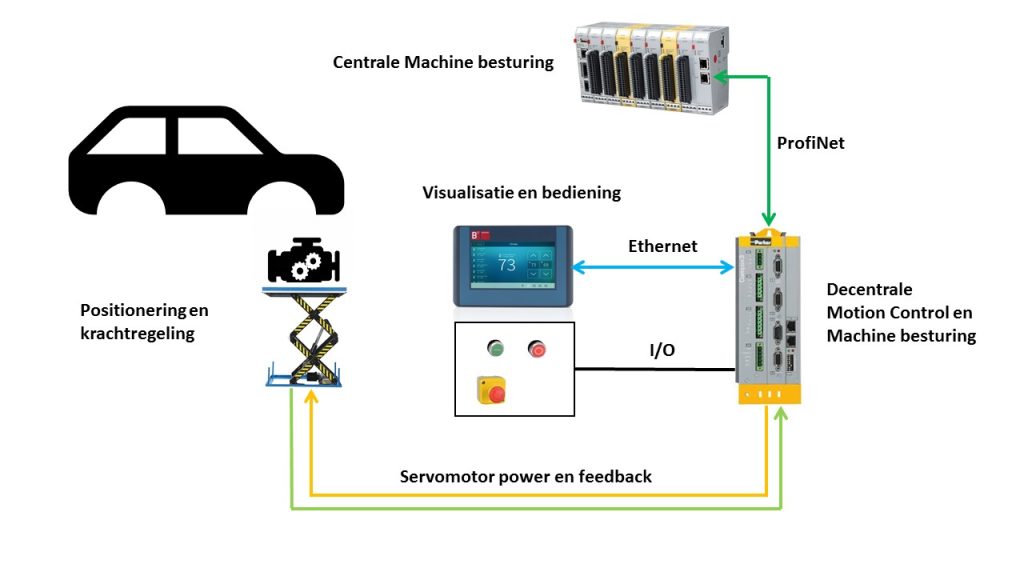

“Everyone has a clear image of an assembly line for car manufacturing. Motion control solutions are responsible for both positioning the engine and placing the driver’s seat. However, one requires a decentralized system while the other demands a central control.

Positioning the engine in the car is not easy but relatively straightforward. It needs to be brought into position with a single linear motion (from above or below). After all, a mechanic in the garage should be able to remove it as well. On the other hand, the car seat needs to be positioned with a much more complex movement, involving a turn and avoiding hitting the door. This multi-axis movement, with significant interdependence, requires a much higher level of control intelligence. For instance, a decentralized positioning for the engine and a central system for placing the seat would be the optimal solution in this case.”

[fl_builder_insert_layout id=11234]

Advantages of Decentralized Motion Control Intelligence

Independence from the type/brand of equipment when control is executed via a standard communication bus

Defining technical responsibilities

Specific control tasks can be executed close to the source

Advantages of Centralized Motion Control Intelligence:

A unified automation environment

Synchronization of servo axes

Control of multi-axis kinematic movements

Dependency Determines Central or Decentralized Motion Control Choice

According to Roel van der Mark, the choice between decentralized or centralized motion control intelligence is largely determined by the (mutual) interdependence of the different axes:

“When a decentralized system needs to perform a complex movement, each motor – each axis is driven by a motor – relies on information from the other motors. For instance, the Y motor can start moving only when the X motor reaches a certain position. And this is just an example of the interdependence between two axes; in many applications, there is also a Z-axis and potentially rotation is added. In a decentralized solution, this requires significant data exchange at high speed and substantial processing power, quickly leading to complexity. This becomes inefficient and unnecessarily complex. In such cases, a centralized solution is often a better choice.”

However, we can also reduce this complexity and minimize interdependence. In practice, there are often significant advantages to a decentralized solution. Returning to the example of the car assembly line, it’s likely not desirable for both the seat placement and the engine placement to be controlled by the same system. At the ‘control’ level, the command ‘place engine’ can be given, but the control, position, and force regulation can be managed by a decentralized system.

An additional advantage here is that the person responsible for programming the ‘control’ system doesn’t need to be an expert in Motion Control. They simply need to know how to give the command ‘place seat’. In practice, machine builders often opt for a decentralized application of a “central motion control” solution.

Choosing Central or Decentralized Motion Control System

In practice, VARIODRIVE typically goes through the following questions when addressing this issue:

1. What motion is necessary and how can we make it as simple as possible?

2. Which motors and mechanical components will we use for this purpose?

3. How do we ensure that the motor(s) precisely execute the necessary motion(s)?

4. Can this be done centrally or should it be done decentrally? (dependency)

Roel adds:

“Our customers – machine builders – often know very well what they are doing. The answer to the first question is often given. At the same time, there are occasions where we can still make a difference here. By sharing our experience with different applications and solutions, we sometimes get closer to the right solution. In any case, we make a difference with the subsequent questions; the answer is always a collaboration between the capabilities of the components and the requirements of the application. We provide our customers with insights into the possibilities – both central and decentralized – and their consequences, so that we can make the right choice together.”

Why VARIODRIVE

Central or decentralized, many customers prefer to entrust the responsibility for a Motion Control solution to VARIODRIVE. The delineation of technical responsibility not only provides peace of mind and assurance but also means that your application engineer doesn’t need to be an expert in all fields. After all, which engineer is 100% proficient in all the technology found in complex machines? VARIODRIVE’s Application Engineers assist during product development, install the integrated solution, train your staff in its use, and ensure its proper functioning.

That’s why we’re more than willing to discuss your motion control challenge with you. We can draw on our years of experience and in-depth knowledge of contemporary technology to contribute to your process. Feel free to contact us at 0186-636280.