Busch Microsystems: Positioning systems for high-tech applications.

How do you achieve the highest possible accuracy for a positioning system? VARIODRIVE partner Busch Microsystems has been supplying granite positioning systems to various high-tech markets since 1999. In this article, we talk to CEO Nicola Busch about her company, market developments, and their recent introduction of a lightweight material that can replace both steel and granite.

“Even in these turbulent times, we show all our customers that Busch Microsystems has the knowledge, capacity, and flexibility to deliver a high-quality, reliable positioning system.”

It’s evident that for Nicola Busch, CEO of Busch Microsystems, the changing customer needs take center stage. She handles the commercial responsibilities while her father, founder Winfried Busch, manages the technical aspects. The supplier of granite positioning systems – including gantry systems, XY, linear, and lifting tables – has evolved over the years to become a manufacturer of complete turn-key system solutions.

Active in demanding high-tech markets

“Laser technology is particularly interesting as it’s rapidly evolving and impacting a wide range of markets,” Nicola says. “The demands for precision keep rising, which means the accuracy of our systems must also continue to improve. At the same time, each market has its own specific requirements. For example, both the semiconductor and medical markets are high-tech, yet each has its unique conditions. It’s always a fantastic challenge to adapt our base systems to meet the specific demands of new markets. Technical innovation and the application of new materials are essential in this process.”

Carbon Fiber composite replaces granite

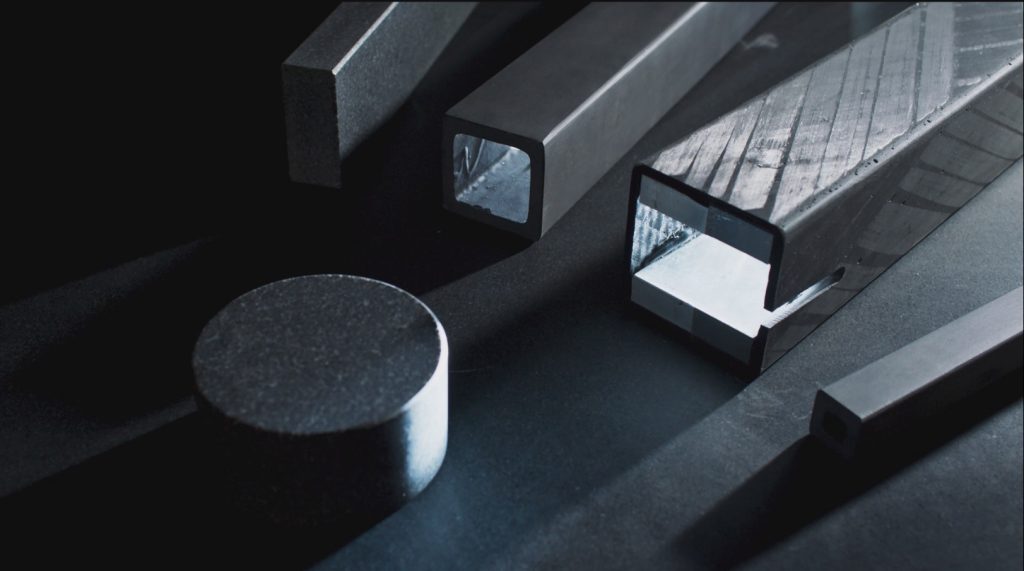

The high stiffness of granite has traditionally allowed positioning systems made from this material to provide greater dynamics and precision. However, there’s now a new material that is lighter but offers the same stiffness: Carbon Fiber Composite (CFC). Processing carbon fiber used to be a significant challenge, but Busch Microsystems can now process CFC as smoothly as granite. This enables weight savings of 40% and 70% compared to granite and steel, respectively.

“By closely collaborating with the engineering teams of our customers, we can determine how to utilize a material like CFC to achieve the desired accuracy. We then challenge ourselves to surpass those expectations in our collaboration. And fortunately, we succeed.”

Busch Microsystems has created the following video about this new material:

Partnership with VARIODRIVE

“VARIODRIVE is a crucial partner for us; they often come with challenging, demanding applications that require us to apply our expertise in new ways. That’s also how we got in touch initially, through a mutual partner who introduced us to an interesting project we eventually collaborated on. Ultimately, both companies simply speak the same language, are solution-oriented, and always seek the best technical solution. Customers benefit from this strong collaboration. VARIODRIVE’s expertise in motion control applications is immense, and combined with their understanding of the Dutch market, it’s exactly what we look for in a partner. Busch supports VARIODRIVE with our mechanical knowledge and production expertise; they know exactly which applications align well with us. Together, we make a fantastic team.”

High-tech precision positioning systems

When we ask Nicola about the future, she circles back to the changing customer needs before discussing Busch Microsystems’ ambitions:

“The demands in all the markets we operate in are increasing, while there is also a strong emphasis on minimizing waste and raw material consumption. In the semiconductor and optical markets, new standards need to be set, and in pick and place applications, higher speeds need to be achieved (while maintaining the same precision). But accuracy is also becoming increasingly important in medical applications, additive manufacturing, micro welding, and display panel production. Therefore, we must continue to develop and innovate to support our customers.

We’re not only innovating and developing to meet these demands, but we also want to offer customers a more complete product. Busch Microsystems is increasingly providing turn-key solutions to our customers. This is the key to growth; we want to become better and better at what we do and offer our solutions in more countries. We recently started exporting our products to the US, and in the coming years, we want to expand our presence there.

We’re also expanding our collaboration with VARIODRIVE. We believe that together, we can develop even more challenging motion applications that make a difference for our mutual customers.”