SK2

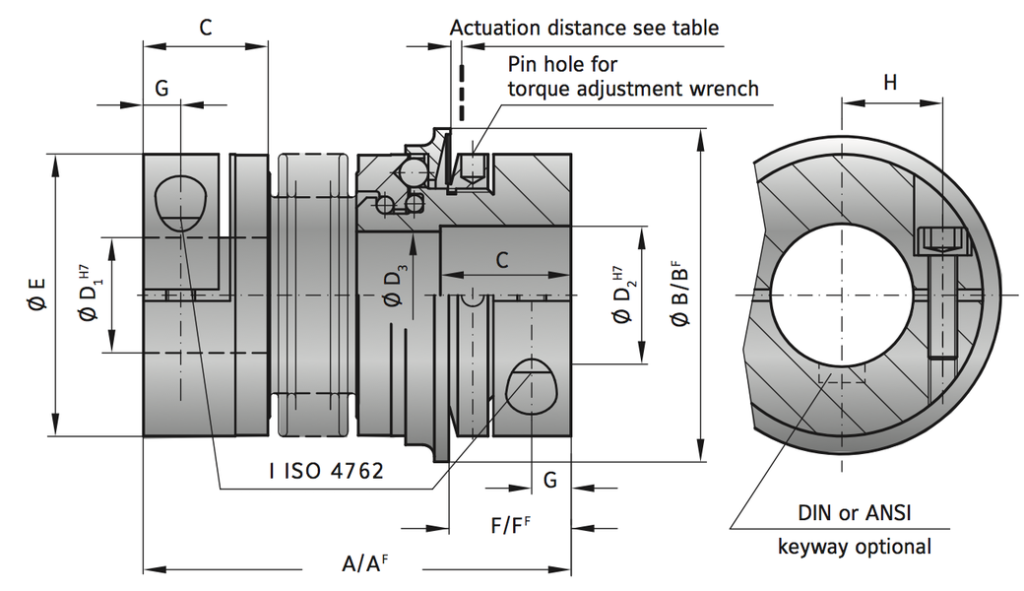

Torque limitersThe SK2 safety coupling from R+W Couplings is easy to assemble and disassemble. Additionally, this precision coupling features fast and accurate disengagement detection and disengagement. Due to the friction clamp connection, this safety coupling is completely free of play. The maximum torque of the SK2 coupling can also be manually adjusted using an adjusting wrench. This key can be ordered separately. Thanks to the forcibly formed bellows shape, the element can simultaneously compensate for lateral, axial, and angular misalignment errors. For specific inquiries about safety couplings or other precision couplings, please contact VARIODRIVE.

- Bestelcode instructies

- Uitleg veiligheidssystemen

- ATEX instructies

- Datasheet SK2

- Manual SK koppelingen

| SK2 Series | 1,5 | 2 | 4,5 | 10 | 15 | 30 | 60 | 80 | 150 | 200 | 300 | 500 | 800 | 1500 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Overall length | A | 42 | 46 | 51 | 57 | 65 | 65 | 74 | 75 | 182 | 87 | 95 | 102 | 112 | 115 | 127 | 116 | 128 | 128 | 140 | 139 | 153 | 163 | 177 | 190 | 223 |

| Overall length ("F" Version) (mm) | AF | 42 | 46 | 51 | 57 | 65 | 65 | 74 | 75 | 82 | 87 | 95 | 102 | 112 | 117 | 129 | 118 | 130 | 131 | 143 | 142 | 156 | 167 | 181 | 201 | 232 |

| Fit length (mm) | C | 11 | 13 | 16 | 16 | 22 | 27 | 31 | 35 | 35 | 40 | 42 | 51 | 48 | 67 |

| Inside diameter range H7 (XL-Hub) (mm) | D1/D2 | 3-8 | 04-12 | 5-14 | 6-16 | 10-26 | 12-30 | 15-32 | 19-42 | 19-42 | 24-45 | 30-60 | 35-60 | 40-75 | 50-80 |

| Outside diameter of coupling (mm) | E | 19 | 25 | 32 | 40 | 49 | 55 | 66 | 81 | 81 | 90 | 110 | 123 | 134 | 157 |

| Moment of inertia (10-3 kgm2) | Jges | 0,01 | 0,01 | 0,01 | 0,02 | 0,02 | 0,06 | 0,07 | 0,10 | 0,15 | 0,27 | 0,32 | 0,75 | 0,80 | 1,80 | 1,90 | 2,50 | 2,80 | 5,10 | 5,30 | 11,5 | 11,8 | 22,8 | 23,0 | 42 | 83 |

| Approximate weight (kg) | 0,047 | 0,07 | 0,2 | 0,3 | 0,4 | 0,6 | 1 | 2 | 2,4 | 4 | 5,9 | 9,6 | 14 | 21 | |

| Torsional stiffness (10³ Nm/rad) | CT | 0,7 | 1,2 | 1,3 | 7 | 15 | 9 | 18 | 20 | 15 | 39 | 28 | 76 | 55 | 129 | 85 | 175 | 110 | 191 | 140 | 420 | 350 | 510 | 500 | 780 | 1304 |

| Lateral ± (mm) | max. | 0,15 | 0,15 | 0,20 | 0,20 | 0,25 | 0,20 | 0,30 | 0,15 | 10,20 | 0,20 | 0,25 | 0,20 | 0,25 | 0,20 | 0,25 | 0,20 | 0,25 | 0,25 | 0,30 | 0,25 | 0,30 | 0,30 | 0,35 | 0,35 | 0,35 |

| Angular ± (degree) | max. | 1 | 1 | 1,5 | 1,5 | 2 | 1,5 | 2 | 1 | 1,5 | 1 | 1,5 | 1 | 1,5 | 1 | 1,5 | 1 | 1,5 | 1,5 | 2 | 1,5 | 2 | 2 | 2,5 | 2,5 | 2,5 |

| Screw ISO 4762 | I | M2,5 | M3 | M4 | M4 | M5 | M6 | M8 | M10 | M10 | M12 | M12 | M16 | 2xM16 | 2xM20 |

| Tightening torque of the fastening screw (Nm) | I | 1 | 2 | 4 | 4,5 | 8 | 15 | 40 | 50 | 70 | 120 | 130 | 200 | 250 | 470 |

| Distance between centerlines (mm) | H | 6 | 8 | 10 | 15 | 17 | 19 | 23 | 27 | 27 | 31 | 39 | 41 | 2x48 | 2x55 |

| Distance (mm) | G | 3,5 | 4 | 5 | 5 | 6,5 | 7,5 | 9,5 | 11 | 11 | 12,5 | 13 | 17 | 18 | 22,5 |

| Distance (mm) | F | 12 | 13 | 15 | 17 | 19 | 24 | 30 | 31 | 31 | 35 | 35 | 45 | 50 | 63 |

| Distance, ("F" Version) (mm) | FF | 11,5 | 12 | 14 | 16 | 19 | 22 | 29 | 31 | 30 | 33 | 35 | 43 | 54 | 61 |

| Adjustment range available from - to (approx. values) (Nm) | TKN | 0,1-0,6 0,4-1 0,8-1,5 | 0,2-1,5 0,5-2 | 1-3 3-6 | 2-6 4-12 | 5-10 8-20 | 10-25 20-40 | 10-30 25-80 | 20-70 30-90 | 20-70 45-150 80-180 | 30-90 60-160 120-240 | 100-200 150-240 200-320 | 80-200 200-350 300-500 | 400-650 500-800 650-850 | 650-800 700-1200 1000-1800 |

| Adjustment range available from - to (approx. values) ("F" Version) (Nm) | TKN | 0,3-0,8 0,6-1,3 | 0,2-1 0,7-2 | 2,5-4,5 | 2-5 5-10 | 7-15 | 8-20 16-30 | 20-40 30-60 | 20-60 40-80 | 20-60 40-80 80-150 | 80-140 130-200 | 120-180 160-300 | 60-150 100-300 250-500 | 200-400 450-800 | 1000-1250 1250-1500 |

| Actuation ring Ø (mm) | B | 23 | 29 | 35 | 45 | 55 | 65 | 73 | 92 | 92 | 99 | 120 | 135 | 152 | 174 |

| Actuation ring Ø, ("F" Version) (mm) | BF | 24 | 32 | 42 | 51,5 | 62 | 70 | 83 | 98 | 98 | 117 | 132 | 155 | 177 | 187 |

| Diameter | D3 | 9 | 12 | 14 | 20 | 21,1 | 24,1 | 32,1 | 36,1 | 36,1 | 42,1 | 58,1 | 60,1 | 60,1 | 68,1 |

| Actuation distance (mm) | 0,7 | 0,8 | 0,8 | 1,2 | 1,5 | 1,5 | 1,7 | 1,9 | 1,9 | 2,2 | 2,2 | 2,2 | 2,2 | 3 | |

| Lateral spring stiffness | 70 | 40 | 30 | 290 | 45 | 280 | 145 | 475 | 137 | 900 | 270 | 1200 | 420 | 920 | 255 | 1550 | 435 | 2040 | 610 | 3750 | 1050 | 2500 | 840 | 2000 | 3600 | |

| 1,5 | 2 | 4,5 | 10 | 15 | 30 | 60 | 80 | 150 | 200 | 300 | 500 | 800 | 1500 |

- All

- Datasheets

- Manuals

- Datasheets

- Datasheets

- Datasheets

- Datasheets

- Manuals

How can I place an order with VARIODRIVE?

You can place an order with VARIODRIVE by sending your request to orders@variodrive.nl. Your request will then be processed directly by our internal sales team.

Why should I choose a complete solution from VARIODRIVE?

By choosing VARIODRIVE’s complete solution, you won’t need to worry about integrating different drive components into the machine’s drive chain. We stand behind our complete solution and can guarantee its functionality.

Why should I choose VARIODRIVE's system warranty?

Due to our in-depth knowledge of our products and their integration into applications, we can provide a system warranty. At that point, we guarantee that the application will function using our motion control and traction solutions.

How can I download 3D drawings?

For most products on our website, you can download the 3D files. If the desired 3D file is not available, please contact sales@variodrive.nl, and we will send you the 3D file as soon as possible.

How can I download software?

You can download the necessary configuration software for most products on our website. For a few products, this might not be possible. In such cases, please contact sales@variodrive.nl, and we will assist you as soon as possible.

Have you found everything you need?